As a follow on to my visit with the Lafayette Cloud Jockeys and a pending September trip to Iowa to attend the Sig Fly-In, I am attempting to get some things in order so that I have some planes to fly. The Cloud Jockeys and LOFT both have an August 15 sailplane meet, as well, so I will be headed north to Fort Wayne since I am the VP for LOFT instead of joining the Cloud Jockeys at the South Field.

So, looking around, I attempt to define what I can achieve. The ever-durable Positron II is a sure bet, as is my woe-begotten Push-E Cat V5 development mule. I would like to finish the Miss Priss and parade that in public in September. The other oft neglected project is the old Skimmer 400 that I received from my brother-in-law a few years back that I am converting into a T-tail. That’s close enough to done that I think I can finish it for September, but not next Tuesday.

I have a 1.3 m Valiant that is 100% airworthy. All it needs is a charged pack. Ditto for a Night Radian. I have a micro F4F and a micro P-47 that I could fly Tuesday. Another pair of possibles for September are Pat Mattes’ old Ace Cessna knock-off that he threw together oh so many years ago and another inherited brother-in-law plane, a Nora originally acquired from Hobby Lobby in the dark ages of Speed 280 and Speed 400 gear drives. Both need upgrades to the current level of brushless/LiPo tech to be easily enjoyed.

Looking at it that way, I guess I do not feel so plane-poor after all. This leaves aside other more ambitious projects that will be recurring blog stories another time.

This post, however, focuses on the actual, real life progress I am making with the Skimmer.

Back in 2017, I started reworking the Skimmer 400. Will had brought the bird in hard on its nose at some point and things were completely shattered up front. Additionally, the empennage was basically Monocote bags of loose balsa sticks.

I got things rolling and was actually making good progress. I was a bit stumped on the motor and mounting, but I could have overcome that.

Then, my wife decided we were moving and things went all to heck and gone.

Now, in 2020, I’m finally getting my plow back in the dirt on this project.

The biggest thing was to get over my hiccup of choosing a motor.

As you can see here, I finally decided what to do and that was to go with Bell-style motors, 28 mm diameter, instead of a bulkhead type mount motor.

The truth is that the 28 mm Bell-types are more flexible for my kind of modeling than the bulkheads. I like the fact that the mount can be bolted to the former without the motor and then the motor secured with set screws. That makes the whole thing very serviceable in my opinion, with a smaller mounting footprint.

This necessitated removing the original Speed 400 mounting plate, which I did using a combination of rat tail file and Permagrit round sanding stick to the outline of an appropriate metric socket. There is plenty of structure left because the original nose plate was a multi-layer piece of German overkill. It is verruh verruh thick up front, which actually made for a solid nose ring after all the sanding was done.

Unfortunately, some hangar rash has also gotten to the Skimmer, some very recently induced: point of fact, I dropped the damned thing on its tail.

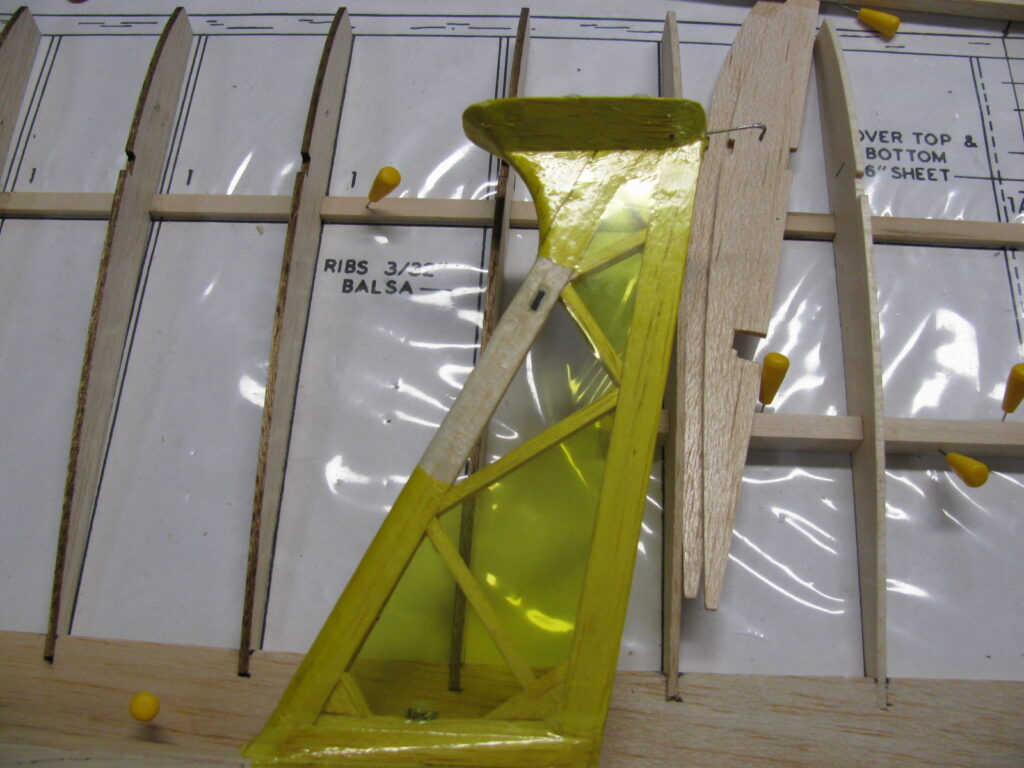

The only damage to the fin was directly in keeping with the discussion that had been had on RC Groups about how T-Tails tend to be fragile for a variety of reasons.

This is especially true when you are talking about ground loops or anything where the horizontal stab contacts a solid object while the rest of the aircraft is still in motion.

In this case, the leading edge of the fin is a balsa composite of 1/16″ strips which I did so that I could run the elevator actuation cable up through the hollow. In hindsight, I really should have either buried some 1/16 basswood or carbon fiber in the middle instead of more balsa.

It’s a one-off, so not a huge engineering concern. I wrestled with splicing in basswood or carbon on the front and rear of the leading assembly, but decided in the end to simply use thin CyA and a little carbon fiber bridge across the crack for reinforcement. I also put a few slits along the grain on the opposite side where the balsa had yielded and wicked CyA into those as well to stiffen up the bent region.

In the photo above, you can also see the “L” I put into the Sullivan cable for going through the elevator push rod. The reason for that is:

When I dropped the fuselage on its tail, the 1/16″ ply control horn I custom-made disintegrated.

After doing some checking on-line, I acquired some 0.060 stryene sheet to run in the laser printer to make a new control horn. I hate to say it, but I think I’m going to trust that to be a bit more durable in this situation.

The other big decision was to not to try and shoehorn in a ridiculous battery pack and to go with something easily available, so I grabbed an E-Flite 800 mAh pack. I think the key to getting better performance for this plane is not to try and stuff some ridiculously high-powered system in it. Rather, I want to take advantage of the improved efficiencies of the brushless/LiPo combination to improve the handling and sink rate of the plane.

The only piece of hardware left that I need to complete the package is the folding prop/spinner assembly. I have ordered a 36 mm spinner assembly from Esprit Tech, who seem to be the main portal for quality German sailplane stuff to the USA now. I also picked up a couple of extra prop sets to try and see what kind of current draw they give me.

More on this when I get the styrene sheet and spinner/props in.