Tick tock goes the clock and I’m running down the minutes until I actually begin shipping Push-E Cats again. First clue that things are getting close is the cover page in the image shown at right, here. Yes, Virginia, I am actually doing real live page layout in a desktop publisher. Fear the coming word dumpage.

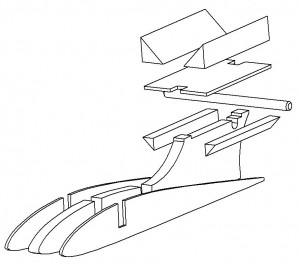

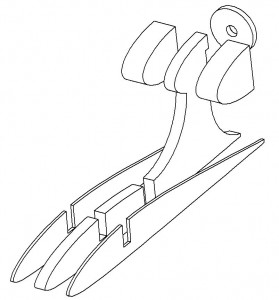

I would like to note at this time that it took many more hours to actually futz around with the stupid picture of the Push-E Cat prototype for the cover than it did to do actual honest to goodness solid CAD exploded views of the motor mounts. I HATE image editing. Fortunately, it’s not an unreasoning hatred. I know that I hate it because I don’t know what I’m doing. All day today as I was messing with the picture, I kept thinking to myself, “Self, go to IPFW in the Spring and take a damned photo editing class. You’re gonna need it.”

Of course, today did not lack for issues with CAD, either. I had not touched my copy of Vellum Solids seriously since I last did an update to the V3a instructions in 2002. As a result, when I started in on doing the illustrations based off my Vellum layouts, it was like learning to ride a unicycle all over again. The extra special bonus is that Solids seems to hate the computer I’m currently using. It runs fine on my old computer (which currently is in the service of my eldest daughter), but it really dislikes being forced to run on my “downgraded” XP box (i.e. I killed the Vista install that came on my box and replaced it with XP because, honestly, Vista sucked.)

In any case, it took a morning epiphany that “Maybe the software is screwed up” before I finally managed to break through and start making progress again.

So, having face a variety of issues that have little or nothing to do with actually cutting parts for kits, I will sit down tomorrow to do battle with the dreaded CAD and publishing systems to try and knock out the instructions for this thing.

One thing about making kits, there’s always one more thing. Still, I’ve done this before so I do have some idea of what I’m up against. And going through this for the PEC V5 should make doing the same thing for the Flat Cat a cinch.

Right now, my biggest ancillary worry is finalizing the procedure for installing the ailerons. After that, I’m running a test to compare using .047 wire for all push rods on the servo ends as opposed to using .063 wire. With all these teeny servos, when you push through a 1/16″ hole in the arm for the rod, there’s damned little nylon left to absorb the shock. If you use .047, the Z-bend slips right into the little factory holes.

I think it’s going to work. I’m just waiting for the Pro-Bond to set before I try a “pull-out” test.

After that, all that’s left is a quick design for some plywood control horns for the PEC V5 ailerons and the Flat Cat everything. I can almost taste the EPP smoke and feel the router vibrations as I type.